Choosing the right equipment can be overwhelming, whether it’s for a new car or concrete construction. For concrete contractors, selecting the right screed is crucial for achieving a smooth, level finish on concrete projects. This guide will help you navigate the various screed options available to maximize productivity and return on investment (ROI).

Roller Screeds for Versatility

Roller screeds broadly consist of a detachable pipe connected to a drive head with an extended handle for upright, ergonomic operation. Known for their minimal setup and ease of use, roller screeds deliver consistent, quality results with less dependence on the operator’s skill.

They use a spinning motion to move concrete, a method that reduces operator fatigue and allows for improved integration of aggregate throughout the pour compared to vibratory methods that may cause the aggregate to settle. Versatile and adaptable, roller screeds can handle pours up to 30 feet wide, depending on the power source.

With detachable designs, roller screeds are a highly portable option when compared to bulkier and heavier screeds like laser screeds. Some manufacturers even offer linkable pipe sections to increase portability and versatility.

Crews are able to quickly adapt to various jobsite needs thanks to features like three-way adjustable and lockable handles for ease of operation, and kickstands to keep the drive head and handle out of the concrete.

When it comes to roller screeds, contractors have four different power options to choose from: battery, corded, hydraulic and gas-powered.

Battery Power Screeds:

Battery-powered roller screeds are easily maneuverable and can handle pours up to 22-feet-wide. These versatile machines can be especially useful for contractors working in basements or factory settings indoors, at farms, or communities in remote locations.

Depending on the slump and pipe length, a contractor can screed off 1,800 to 2,500 square feet of concrete with just one fully charged battery. Battery operation provides fume-free screeding for those working in closed off environments, or any area where fumes may be a concern. These also generally require less setup time, and no cords or hoses are in the way on the site. Some battery-powered roller screeds can also provide cross-platform use by using the same rechargeable lithium-ion batteries found in common handheld power tools.

For special projects, such as circular pours, battery-powered roller screeds provide a convenient single-push-button directional change. This allows contractors to easily change their screeding direction to avoid cold joints or other structural flaws that can occur when concrete cures unevenly. Other screed types may require a complete disassembly, drive head rotation, and reassembly of the screed to reverse direction.

Despite the conveniences battery-powered roller screeds offer, if power accessibility isn’t a concern or portable jobsite generators are abundant, some contractors may opt for a corded screed.

Corded Screeds:

Corded electric roller screeds offer many of the same benefits and capabilities as their battery-powered brethren. They are fume-free for indoor jobs, and some provide a single-push-button directional change for screeding unique pours. With a nearby outlet or reliable generator, contractors can have the reassurance and convenience of seemingly endless power.

While enjoying the convenience of power, contractors must consider proper care to ensure the cords don’t become tangled, unplugged or damaged while on the jobsite. And relying on a separate power source, like a generator, can come with its own worries. That can include staying on top of fuel availability, general maintenance or fume concerns.

Battery and corded power can offer an immensely convenient and versatile screeding solution to any contractor’s fleet, but some heavy-duty applications, like road drainage and ditch liner pours, require large custom drums and a screed powerful enough to drive them. This is where hydraulic roller screeds shine.

Hydraulic Screeds:

Hydraulic-powered roller screeds have the power to move up to six inches of concrete along a pour while the operator remains in a standing position. Additionally, most hydraulic roller screeds accept six-inch tube in lengths up to 30 feet. Some manufacturers also offer custom drums made to various job specifications, such as sidewalks, parking lots, residential streets, large highway ditch liners, and more.

Like corded screeds, hydraulic screeds require a separate power source.

Look for a manufacturer that provides a portable

hydraulic power pack

to match their hydraulic screed’s exact specifications. With this option, contractors don’t have to tie up a host machine to power their screed.

These screeds are also generally two to three times heavier than battery and corded roller screeds, making it possible to take on heavy-duty jobs. Contractors should consider how to accommodate the additional weight before committing to these powerful screeds.

Gas Power Screeds:

Gas-powered roller screeds have a similar setup as the other roller screeds but with a motor attached to the drive head. These screeds offer another option for contractors who typically screed large pours that require a longer pipe, often up to 30 feet wide.

The motor produces screeding power that rivals that of hydraulic screeds and offers a viable, familiar alternative for those preferring a gas engine.

Unlike the other screeds, more care is required with gas-powered machines. The screed motor needs to be in an upright position to avoid gas and oil from leaking out. This may prove challenging due to the heavy weight of the engine on the drive head.

These screeds have location limitations as well, as they cannot be used indoors due to the exhaust and fumes from the engine. Engine vibrations present another area of concern. The high vibration from the engine can cause the throttle cable to slip, which may necessitate continuous readjustment.

Truss Screeds for Length

Unlike roller screeds, truss screeds rely on vibration to level concrete, offering a major design shift from spinning pipes.

Truss screeds are expandable, featuring multiple sections that resemble a truss design, maintaining rigidity for lengths even beyond 60 feet. Truss screeds can be an excellent option for the largest jobs, like screeding an entire roadway.

Vibrations from a motor attached to the truss carry throughout the screed as contractors guide it along concrete forms, flattening and settling the concrete to remove trapped air, increase concrete strength, and provide a smooth finish. However, due to the vibration, these screeds are generally not used on a slope.

The aggregate in concrete tends to settle with vibration and unevenly dispersed aggregate can create spots of varying strengths that can result in structural flaws and damage over time.

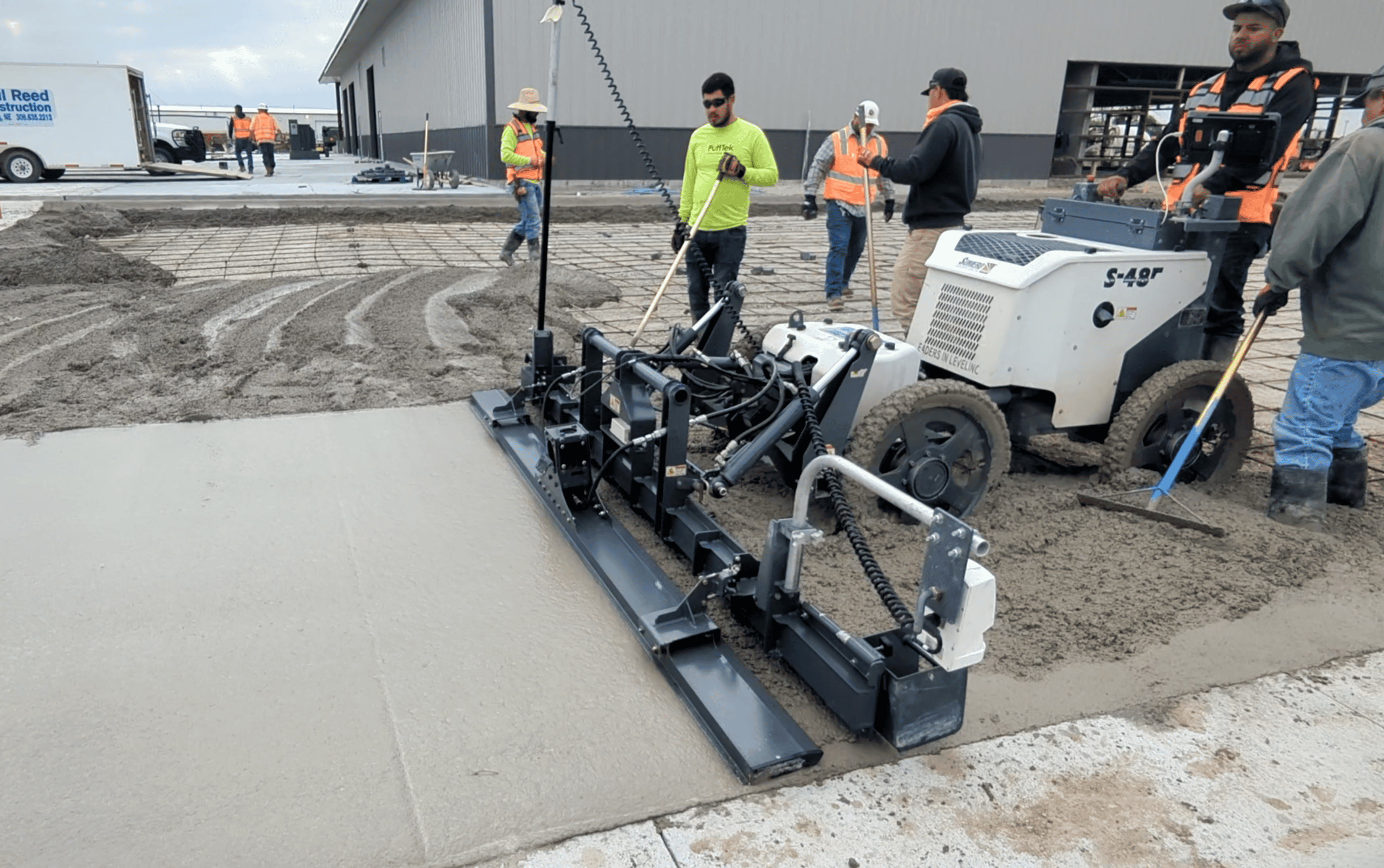

Laser Screed Precision

Laser screeds, a newer addition to the market, are gaining popularity for large pours requiring high precision. They can be found in a variety of styles ranging from telescopic attachments to ride-along machines.

The screed’s laser arm ensures a precise, accurate, and evenly leveled surface while reducing the need for excessive labor. The average laser screed can screed approximately 240 square feet of concrete in one minute. This equipment is a game changer for the concrete industry.

While laser screeds offer many benefits, their upfront cost can be significant, with prices reaching up to $350,000.

Additionally, some of the widest laser-guided screeds available on the market have a maximum width of 20 feet, making their functions more specialized and significantly affecting their overall versatility.

Power Screeds for Single Operators

Power screeds, also known as wet screeds, offer an assisted-hand screeding method. They consist of an engine and extended handle attached to a traditional board/blade in contact with the concrete, using vibration to level it. These tools require significant skill and experience to operate effectively.

Although more ergonomic and efficient than traditional hand screeding, power screeds require the operator to stand in the poured concrete while screeding. The vibration has similar benefits and drawbacks to that of the truss screed. Due to their one-man operation and center support, manufacturers typically limit the board/blade sizes to around 15 feet.

Traditional Hand Screeds for Low Cost

Traditional hand screeding typically involving a wooden board may suffice for small, occasional jobs. However, experienced contractors are well aware of the physical strain and general inefficiency of this method, which involves stooping over a heavy board and manually sawing it back and forth along forms.

Although the materials have evolved from hefty two-by-four lumber to lighter-weight aluminum alloy bars, the design and method has largely remained unchanged.

In addition to the back-breaking labor, hand screeding methods using boards require the skill of an experienced professional to remain true to grade and achieve consistent results since there’s no assistance from vibration or a spinning pipe. This can prove challenging on large pours, even with decades of experience.

Closing Thoughts

Finding the ideal concrete screed requires careful consideration. But picking the right one for your crew and site is essential for maximizing productivity and achieving a smooth, level finish. By understanding the features and applications of each screed type, contractors can make informed decisions to enhance their concrete work and improve ROI.

If you still aren’t sure which option is best for your applications, fill out the form below, give our team a call at 785-467-3132, or email us at info@curbroller.com.